Feature 1

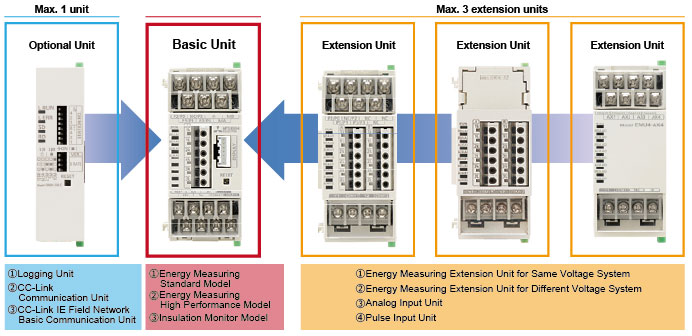

Additional units (Optional unit, Extension unit) be added to expand systems in « building block » style.

Feature 2

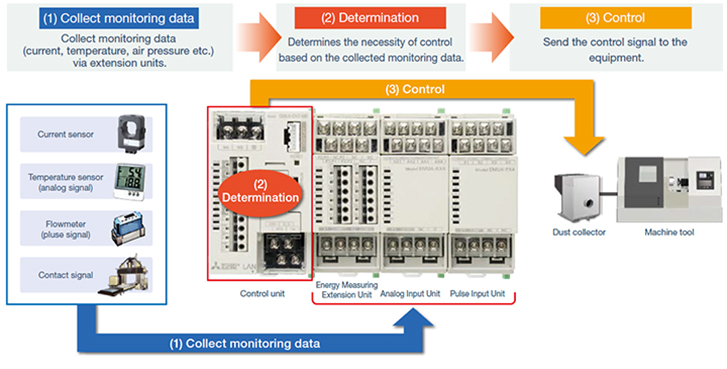

- By combining the control unit (EMU4-CNT-MB) and extension unit, it is possible to automatically control the equipment in conjunction with the measured values!

- By using a dedicated engineering tool (EMU4-KNET), control can be performed simply by setting control parameters!

*Dedicated engineering tools can be downloaded from the FA Global site.

| Control details *1 | Description |

|---|---|

| Scheduled control | The control unit sends the contact signal to the equipment based on the time schedule. The 24hour based time schedule have to be set in advance. |

| Interlocked control |

Control by contact signal : The control unit sends the contact signal determined by comparing the collected data with target value, comparing collected data with each other or comparing the status of contacts. Analog output control : With this function, the analog output value corresponding to the measured value is calculated and controlled by presetting the upper and lower limits of the measuring value. |

| Compressor control *2 | This function performs energy-saving operation by switching the compressor’s operation mode (operation (load state), operation (unload) state, stop state) to achieve the optimum piping pressure. Two to four compressor units can be controlled. |

*1: The minimum control cycle based on the collected monitoring data is one minute. For details, refer to the instruction manual.

*2: The compressor that shifts to each operation mode in response to the contact output state shown below is the compressor that can be connected and controlled.

| Contact | Compressor operation mode | ||

|---|---|---|---|

| Operation (load) state | Operation (unload) state | Stop state | |

| Load Unload | ON | OFF | OFF |

| Operation | ON | ON | OFF |

| Stop | ON | ON | OFF |

Feature 3

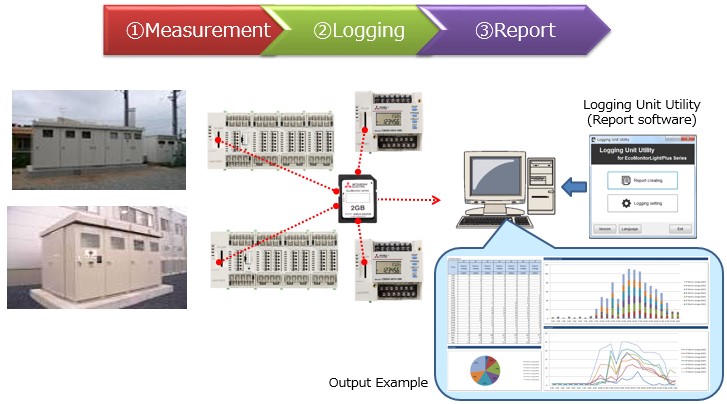

- Collect energy data into a SD memory card from EcoMonitorPlus or EcoMonitorLight.

- Logging Unit Utility can make a report from collected data in SD memory card.

Logging Unit Utility can be downloaded for free from here.

Feature 4

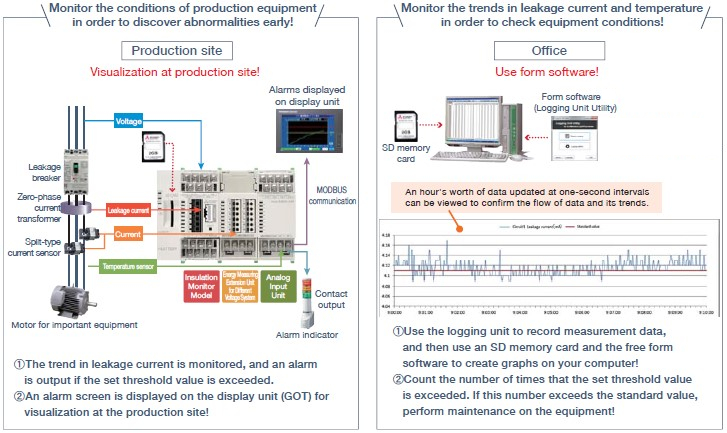

Monitoring the trends in electric leakage, load current, and temperature allows you to perform preventive maintenance to avoid equipment failure.

These types of equipment require preventive maintenance :

![]() Equipment that can result in significant loss if it fails.

Equipment that can result in significant loss if it fails.

![]() Equipment that runs continuously or for many hours.

Equipment that runs continuously or for many hours.

![]() Equipment with cables that easily deteriorate due to moisture or oil.

Equipment with cables that easily deteriorate due to moisture or oil.

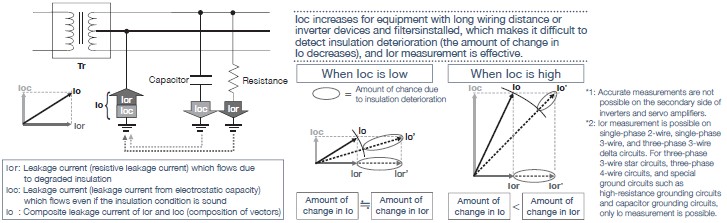

Method of leakage current measurement (Io and Ior measurements)

Feature 5

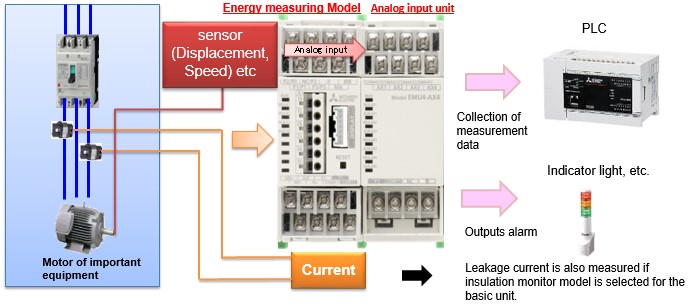

Monitor the failure signs of equipment with analog input unit.

Case study of automobile manufacturer :

![]() To monitor the failure signs of important equipment, measure « current, temperature, vibration » of motor.

To monitor the failure signs of important equipment, measure « current, temperature, vibration » of motor.

![]() Trend monitoring with the data collected by PLC and output an alarm to indicators.

Trend monitoring with the data collected by PLC and output an alarm to indicators.

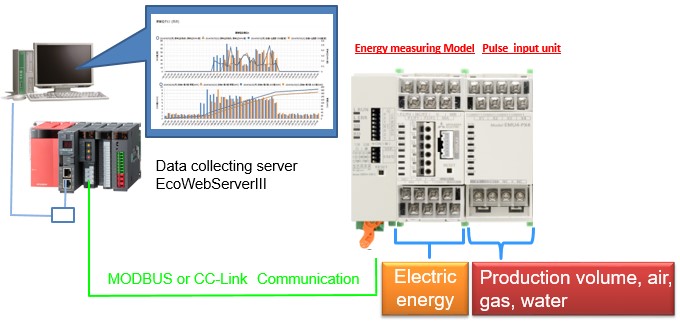

Feature 6

Total energy management is realized by loading data of air, gas, water and other consumption as well as electric energy.

Avis

Il n’y a pas encore d’avis.